Mobile Elevating Work Platforms Safety Guide

The use of Mobile Elevating Work Platforms (MEWPs) has become increasingly prevalent in various industries, including construction, maintenance, and telecommunications, due to their versatility and efficiency in facilitating work at heights. However, the operation of MEWPs also poses significant safety risks if not managed properly. This comprehensive guide aims to provide a detailed overview of the safety considerations and best practices for the safe use of MEWPs, highlighting the importance of a structured approach to risk management and adherence to regulatory standards.

Introduction to MEWPs and Safety Concerns

MEWPs are designed to lift personnel, along with their tools and materials, to elevated positions, enabling them to perform tasks that would otherwise be difficult or dangerous to accomplish. The primary safety concerns associated with MEWPs include falls from the platform, collisions with obstacles, overturning of the machine, and entrapment or crushing. These risks can be mitigated through a combination of proper training, regular maintenance, and adherence to safety guidelines.

Key Points

- Proper training is essential for operators to understand the safe operation and limitations of MEWPs.

- Regular maintenance is critical to ensure the mechanical integrity of the MEWP.

- Conducting thorough risk assessments before each use helps in identifying potential hazards and taking preventive measures.

- Adherence to manufacturer instructions and safety guidelines is paramount.

- Ensuring that all personnel involved in MEWP operations are aware of the safety procedures and emergency protocols.

Pre-Operational Checks and Maintenance

Before the commencement of any work, it is crucial to perform pre-operational checks on the MEWP. This includes verifying that all safety features are functioning correctly, such as guardrails, entry gates, and alarm systems. Additionally, operators must ensure that the MEWP is properly maintained, with records kept of regular servicing and any repairs. The maintenance schedule should be in line with the manufacturer’s recommendations and regulatory requirements.

| Category | Description |

|---|---|

| Daily Checks | Visual inspection for damage, tire pressure check, and functional test of all safety features. |

| Weekly Checks | Thorough inspection of hydraulic and electrical systems, and verification of proper lubrication of moving parts. |

| Monthly Checks | Inspection of wire ropes and chains, and verification of the proper functioning of safety valves and limit switches. |

Operational Safety Considerations

During operation, several factors must be considered to ensure safety. This includes assessing the terrain to prevent overturning, using safety harnesses when working at heights, and maintaining continuous communication with the ground team. Operators must also be aware of their surroundings, including overhead obstacles and the proximity of other workers or equipment. The use of MEWPs in areas with limited visibility or confined spaces requires special precautions, including the use of spotters and communication devices.

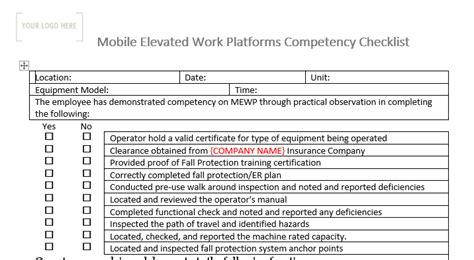

Safety Training and Competence

Safety training is a critical component of MEWP operation. Operators, supervisors, and all personnel involved in MEWP operations must undergo comprehensive training that covers the safe use of the equipment, hazard identification, and emergency procedures. Training should be provided by competent instructors and should include both theoretical and practical components. The training program should be designed to ensure that participants understand the risks associated with MEWP operation and are equipped with the knowledge and skills necessary to mitigate these risks.

Moreover, the importance of ongoing training and assessment cannot be overstated. Operators' competence should be regularly evaluated, and refresher training should be provided as necessary to ensure that their skills and knowledge remain up to date. This not only enhances safety but also contributes to the efficient and effective use of MEWPs.

Emergency Procedures and First Aid

Despite the best preventive measures, emergencies can still occur. Therefore, it is essential to have well-defined emergency procedures in place, including evacuation plans, first aid kits, and a system for reporting incidents. All personnel involved in MEWP operations should be trained in basic first aid and know how to respond in the event of an emergency, such as a fall or equipment failure. Regular drills and simulations can help ensure that the response to emergencies is swift and effective.

What should be included in a MEWP operator's training program?

+A MEWP operator's training program should include both theoretical and practical training on the safe operation of the equipment, hazard identification, emergency procedures, and regulatory requirements. The training should be provided by a competent instructor and should result in the operator being able to demonstrate their competence in the safe use of the MEWP.

How often should MEWPs be inspected and maintained?

+MEWPs should be inspected and maintained regularly, with the frequency depending on the usage and manufacturer's recommendations. Daily checks should be performed before each use, with more thorough inspections conducted on a weekly and monthly basis. Additionally, MEWPs should undergo annual inspections by a competent person to ensure they remain in good working condition.

What safety equipment should be used when operating a MEWP?

+When operating a MEWP, it is essential to use appropriate safety equipment, including a safety harness and lanyard, which should be attached to a secure point on the MEWP. Hard hats, high-visibility vests, and non-slip footwear are also recommended. The use of safety equipment should be in accordance with the manufacturer's instructions and regulatory requirements.

In conclusion, the safe operation of Mobile Elevating Work Platforms requires a multifaceted approach that encompasses proper training, regular maintenance, adherence to safety guidelines, and a thorough understanding of the potential hazards. By prioritizing these elements and fostering a culture of safety within the workplace, the risks associated with MEWP operation can be significantly reduced, ensuring a safer working environment for all involved.